|

|

lowandslow lowandslow |

| February 17, 2015, 3:51am |

|

Wing Man  Posts: 76

Time Online: 19 hours 19 minutes

|

Well - The ribs for my AeroMax are almost finished; I'm currently routing/sanding the bevel on the outside edges of the gussets. Hopefully it won't be too long before I will be able to start mounting them on the spars. The thought of varnishing the wing panels after they are built up is a little intimidating (meaning - it sure looks like a lot of painful drudgery). So - I got to thinking (usually dangerous) and am wondering if the pain would be lessened if I were to tape off the areas that are epoxied to the spar(s) and varnished the unmasked areas now. Then, once the wing panels are complete, it would be somewhat less of an effort to varnish the rest of the wing including the unvarnished areas of the ribs.

Thoughts?

Also, has anyone tested epoxy joints that are put together using wood that has been varnished. I've glued a few joints to see what happens in terms of strength but it occurs to me that someone might have already tried this experiment.

|

| Building an AeroMax My build log is available at http://www.mykitlog.com/lowandslow/ |

|

|

|

|

|

Arthur Withy Arthur Withy |

| February 17, 2015, 7:04am |

|

Happy 1500R owner - building a Jodel D18 Ace Posts: 2,532

Time Online: 32 days 12 hours 14 minutes

|

Only varnish after all glueing is completed....GLUE /epoxy sticks alot better to "raw " wood as it soaks in which forms a very strong joint.....then you varnish before covering.

The varnish is for protection against water. (and humidity too)

cheers Arthur |

|

|

|

|

|

beragoobruce beragoobruce |

| February 17, 2015, 11:57am |

|

Built an Eros - now I'm flying it! Ace Posts: 1,062

Time Online: 19 days 9 hours 48 minutes

|

Arthur is right, glue won't be very strong when applied over varnish.

But.......

You have also correctly sussed that varnishing a finished wing is really fiddly and a pain in the bottom.

I've tried carefully varnishing the areas where it won't be glued, & avoiding top outside surfaces where the fabric will go (another area not to varnish on ribs) & that is really tedious. I've done it now, on the wings, but it took hours.

So I'm thinking that when I come to varnish the fuselage, it might be quicker just to varnish the whole lot, let it dry thoroughly, & then sand off where the fabric will need to be bonded. I'm guessing that will be a lot less hassle than how I did the wings.

I'll post when I've tried it.

Bruce

|

|

|

|

|

|

lake_harley lake_harley |

| February 17, 2015, 1:07pm |

|

Ace

Posts: 1,085

Time Online: 25 days 21 minutes

|

My take would also be that although it is tedious to varnish after assembly it would leave less question about glue joint integrity. By the time you mask the areas not to be varnished and still have to go back to varnish the adjoining areas, there might not really be much time difference.

In your pictures, it looks like the gussets are really thick compared with the 1.5MM gussets on a MiniMAX. What are they made out of? They almost have a corrugated appearance, but maybe it's just the photo.

BTW...nice looking ribs. Satisfying, isn't it?

Lynn |

|

|

|

|

|

stevejahr stevejahr |

| February 18, 2015, 2:11pm |

|

Airbike plans examiner Ace Posts: 200

Time Online: 4 days 11 hours 43 minutes

|

Varnishing... for me this is the most intimidating aspect of wood construction. As friendly as wood is otherwise, this one detail makes me think of alternatives.

How do folks make this less tedious and keep from going crazy?

I have wondered about "varnishing" with epoxy instead (thinned of course). I would expect it to seal the wood and bond better to itself? |

|

|

|

|

|

Tom Tom |

| February 18, 2015, 2:50pm |

|

Ace

Posts: 744

Time Online: 16 days 10 hours 21 minutes

|

Since Stevejahr has asked:

Instead of varnishing I would coat all surfaces with WEST System(tm) epoxy using their Special Coating Hardener. This makes a much more moisture resistant coating than varnish. This stabilizes the wood, making it much less likely to change shape. It also will bond with the epoxy used to glue the ribs to the spar, needing only a light sanding to make sure the surface is "keyed" a bit to give more bonding area. Also there is a very interesting effect in that bending tests on epoxy coated test pieces so that a good epoxy coating apparently fills tiny scratches or nicks, and binds the surface fibers to each other a bit more so that there is actually a small increase in the strength of the piece. Naturally this effect is greatest on thin pieces.

While I am aware that many people talk about "thinning" epoxy, this shouldn't be done. This isn't an opinion. This is chemistry. Epoxy depends upon its lack of volatile materials to prevent the formation of "micro-channels" that pass water vapour. Thin it and it is no better as a coating than varnish. Also epoxy is quite a strong coating, adhesive, and laminating matrix. If you thin it you lose a great deal of its properties.

An epoxy designed for wood construction may need to be thickened at times, with inert fillers of various types for various characteristics, but it should never need to be thinned. Given that the two components are kept warm and you are doing gluing and coating in either a warm shop or in a heated tented area of the shop, WEST System(tm) with the Special Coating Hardener will be thin enough to flow well.

Tom

|

|

|

|

|

|

Bob Daly Bob Daly |

| February 18, 2015, 3:11pm |

|

Ace

Posts: 888

Time Online: 45 days 22 hours 25 minutes

|

One might make a bath of water based polyurethane and dip each rib a couple times. That would be a very quick way that ensures coverage. Sand where the rib is glued to the front spar. Sand the rear spar slot for fit only. |

|

Logged Logged |

|

|

|

|

lowandslow lowandslow |

| February 20, 2015, 6:05am |

|

Wing Man  Posts: 76

Time Online: 19 hours 19 minutes

|

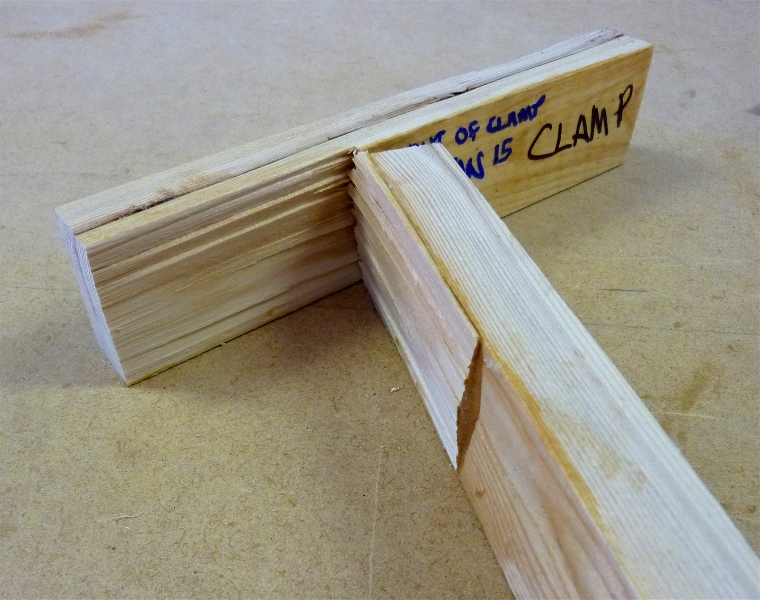

Ace and all - sorry to be slow in responding to your question but I've been BUSY here - on jobs not aircraft related. BUMMER. Anyhow, the laser cut gussets that were sent with the kit (AeroMax is a kit) were 3mm plywood.

I'm getting ready to test the pieces that I epoxied together after applying varnish (polyurethane in my case) - a home brewed test. If the results look promising I'll do more using aircraft sized parts and attempt to find some way of measuring the breakaway force.

What is nice for me - I'm planning on using Oratex material and they want you to glue over varnish. All I have to do is worry about the wood to wood joints.

I'm finished with routing and sanding the bevels on the ribs!!! (WARNING: I'm the slowest mechanic west of the east coast.) What did I get for it - a little rib art. (Tried to include a picture but received an error message. What is the limit on picture size. Maybe that is the problem.) |

| Building an AeroMax My build log is available at http://www.mykitlog.com/lowandslow/ |

|

|

|

|

|

PUFF PUFF |

| February 20, 2015, 12:18pm |

|

Ace Ace Posts: 1,518

Time Online: 34 days 6 hours 18 minutes

|

Size is small, I think 500MB..... |

|

|

|

|

|

lowandslow lowandslow |

| February 20, 2015, 2:47pm |

|

Wing Man  Posts: 76

Time Online: 19 hours 19 minutes

|

Thanks Puff - I tried to edit my last post by adding the photograph that I had in mind but it appears that this system doesn't allow that - so, I've reduced the size and if the photo I had in mind is here - then we know what the problem was.

|

| Building an AeroMax My build log is available at http://www.mykitlog.com/lowandslow/ |

|

|

|

|

|

PUFF PUFF |

| February 23, 2015, 12:21pm |

|

Ace Ace Posts: 1,518

Time Online: 34 days 6 hours 18 minutes

|

oops sorry, 500Kb not MB.... looks like you got it tho. |

|

|

|

|

|

bigbrixx1 bigbrixx1 |

| February 24, 2015, 11:07pm |

|

Ace Ace Posts: 822

Time Online: 20 days 16 hours

|

Yes! Varnishing is Avery tedious job. I varnished each component as they were completed. Much of the time is wasted bringing brush back and forth from container to plane. I found this gadget described in an older EAA book. It cuts the time to varnish by 1/2 to almost 1/3. Oil can, clear tubing secured to brass tube drilled into center of brush. Give it a try! Oh BTW natural hair brushes work better than nylon.

|

| V-max. Finished. Now in phase one flight |

|

|

|

|

|

SloMax SloMax |

| February 24, 2015, 11:34pm |

|

Ace Ace Posts: 206

Time Online: 9 days 18 hours 58 minutes

|

Hi all,

Haven't been here for a while. I love this list.

You guys keep saying Varnish. I hope that is not what is really getting used. I was told by someone who should know that in olden times, varnish was used to seal the wood in planes, and of course after 20-30 years or so, it was breaking down, and exposing the wood to humidity. He said polyurethane was the stuff to use, as it has a very long life out of the sun. I'm sure the special epoxy mentioned above would be fine also.

Also, it's good to seal wood when relative humidity is low. Raw wood drinks water out of the air when it's humid and puts it out when it is dry, much more absorbent through the end grain. You can actually weigh a piece of wood that has been in low humidity, and then put it in high humidity for a few days and weigh the difference on a scale. It's a real eye opener. Well cured wood does better than uncured.

But don't use varnish. |

| Any landing you can walk away from is a good landing. An excellent landing is when, without having to fix it, you can fly the same plane again.

|

|

|

|

|

|

lowandslow lowandslow |

| February 26, 2015, 4:07am |

|

Wing Man  Posts: 76

Time Online: 19 hours 19 minutes

|

TreeTopsTom - so far I really like what I have seen of Oratex. Bought a sample (comes with the glue) and built two test frames to perform a little testing. The first frame was a simple rectangle as I've never done any fabric work. Was fun and came out great. I actually worked hard to not adhere exactly to the instructions in an attempt to see what the performance margins might be. Then I built a 3D frame that had a compound curve structure built in. I didn't do as well there but learned a lot. I'll try to remember to post pictures when I done addressing some of the other issues brought up in this train. BTW - the color is not as bright, deep and shiny as we might like - but that issue is redeemed by a long list of positives (some you already listed). You are correct, cost is a big negative but I won't have to buy a lot of equipment, learn how to sand between coats, expose myself to a lot of potentially harmful chemicals, and will save about 15 pounds according to the best estimates and actual values I've seen.

Bigbrixx1 - Good idea that I will have to try. BTW - what is a "natural bristle brush". No one at my HD knows. In your picture it appears you are using a chip brush and I guess those bristles are not man-made so I have to guess they are "natural".

Slomax - you are on point. I wouldn't use the word varnish except that I know how to spell it and polyurethane is a lot longer. I'm using one from HD that has UV protection built in and goes on and cures nicely. Also, one of the benefits to living in Colorado is really low humidity, especially in a heated shop in the winter time.

BTW - if I remember; tomorrow I will break apart the two samples I glued together, epoxy on wood previously coated with the polyurethane I'm using. More news at 11:00 so they say

|

|

|

|

| Building an AeroMax My build log is available at http://www.mykitlog.com/lowandslow/ |

|

|

|

|

|

beragoobruce beragoobruce |

| February 26, 2015, 7:50am |

|

Built an Eros - now I'm flying it! Ace Posts: 1,062

Time Online: 19 days 9 hours 48 minutes

|

+1 for Brian's oilcan varnish gadget. I made one this afternoon & used it to varnish all the fiddly rear fuse. It is a bit messy, but works really well - and definitely a time saver.

Good on yer, Brian! |

|

|

|

|

|

lowandslow lowandslow |

| February 27, 2015, 4:27pm |

|

Wing Man  Posts: 76

Time Online: 19 hours 19 minutes

|

OK - I know I won't receive a prize from the ASTM for test plans and procedures but I had a little extra time on my hands on the 7th of January and I put one coat of Helmsman Spar Urethane on four pieces of scrap pine just laying around the shop. No sanding, no preparation, just one coat. On the 8th I epoxied them together (2 pieces each using T-8  . One sample cured while being clamped, the other sample I just put a light weight on. Yesterday, I mounted them in a vise and took one hefty swing with a construction hammer - both broke wood and only wood. One took wood from both pieces (the fracture went through the epoxy) and one sample took wood from one side of the joint only. I'll do more tests using material from MiniMax as I'd really like to do as much varnishing as possible before assembling - I know this goes against what some have suggested - because it is easier handling small parts (such as ribs) then big chunks (such as wing panels) and easier to do a better job (getting in all of the nooks and crevasses). Please don't let me get so single minded that I miss an important consideration. Testing continues.

|

|

|

|

| Building an AeroMax My build log is available at http://www.mykitlog.com/lowandslow/ |

|

|

|

|

|

|